STACIR STACIR/AW Conductor

Minimum Order Quantity: 2KM;

Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Shipping: Shipping fee and delivery date to be negotiated. Chat with supplier now for more details;

Secure Payments: Every payment you make is secured with strict SSL encryption and PCI DSS data protection protocols;

Delivery Terms: FOB, CFR, EXW, FAS, DDP;

Payment Currency: USD, EUR, CAD, AUD, GBP, CNY

Share:

Product Description

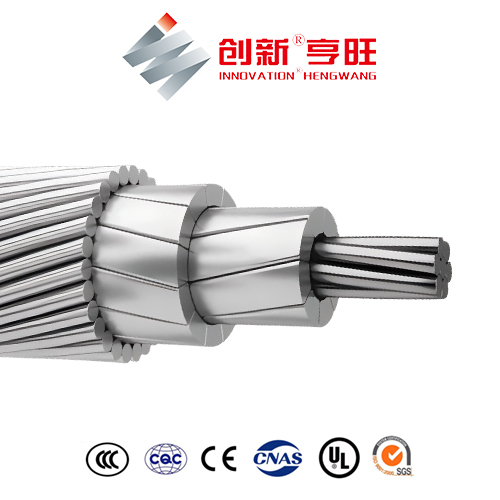

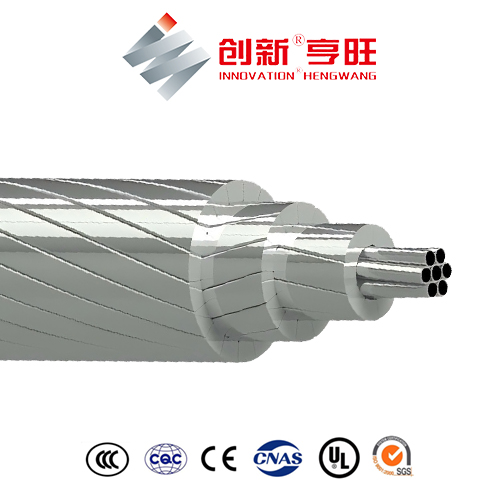

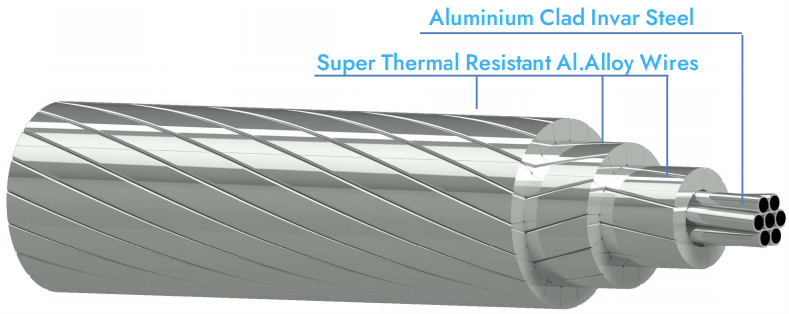

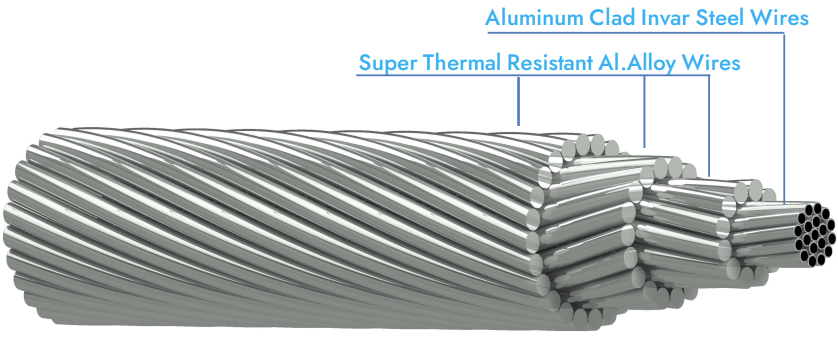

Super Thermal Alloy Conductor Invar Reinforced (STACIR) conductor

Invar Conductor Manufacturer & Supplier from China

STACIR STACIR/AW Conductor Application

Super Thermal Alloy Conductor Invar Reinforced (STACIR) conductor has outer layers composed of Super Thermal Aluminium (STAL) alloy wires that can operate up to 210°C (410°F). The inner core is composed of aluminium clad INVAR wires. INVAR is a metal alloy with 36% Ni in steel.

STACIR/AW conductors are suited for re-conductoring applications. The capacity of existing transmission line can be enhanced by simply replacing the existing conductor without any modification to the tower.

Hi-STACIR/AW, STACIR/AW is normally used to up-rate an existing transmission line by simply replacing the exisitng conductor without tower modification or reinforcement.

STACIR Conductor Construction

Core Wire (INVAR) : Aluminum-clad INVAR Wire/High Tensile Strength Aluminum-clad INVAR Wire

Conductor (STAl) : Super Thermal Resistant Aluminum Alloy Wire used for continuous allowable temperature up to 210℃

Benefits

Can carry 100% more current than that of ACSR of the same size, while maximum sag and maximum working tension remain the same as that of ACSR.

No modification or reinforcement is required to existing towers for uprating transmission and distribution lines.

STACIR STACIR/AW Conductor Standard

IEC, ASTM, JCS 1405

Stacir /Aw & Hi-Stacir/Aw Super-Thermal Resistant Aluminum-Alloy Conductor, (High Tensile Strength) Specifications

SUPER THERMAL RESISTANT ALUMINUM ALLOY CONDUCTOR, ALUMINUM CLAD INVAR REINFORCED (STACIR)

| Conductor Size | Stranding | Cross-Sectional Area | Diameter of Complete Conductor | Weight | Rated Strength | DC

Resistance @ 20°C |

Current Capacity | |||||||||

| No. of Wires | Wire diameter | STAL | Invar | Total | STAL | Steel | Total | |||||||||

| STAL | Invar | STAL | Invar | @ 85°C | @ 150°C | @ 210°C | ||||||||||

| (mm²) | (No.) | (No.) | (mm) | (mm) | (mm²) | (mm²) | (mm²) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 200 | 30 | 7 | 2.60 | 2.60 | 159.28 | 37.17 | 196.44 | 18.20 | 439.31 | 265.01 | 704.32 | 65.38 | 0.1746 | 403 | 690 | 850 |

| 240 | 30 | 7 | 2.90 | 2.90 | 198.16 | 46.24 | 244.39 | 20.30 | 546.54 | 329.69 | 876.23 | 79.92 | 0.1403 | 460 | 794 | 980 |

| 300 | 30 | 7 | 3.20 | 3.20 | 241.27 | 56.30 | 297.57 | 22.40 | 665.47 | 401.43 | 1066.90 | 94.82 | 0.1153 | 518 | 901 | 1114 |

| 300 | 30 | 7 | 3.20 | 3.20 | 241.27 | 56.30 | 297.57 | 22.40 | 665.47 | 401.43 | 1066.90 | 94.82 | 0.1153 | 518 | 901 | 1114 |

| 380 | 26 | 7 | 4.00 | 3.10 | 326.73 | 52.83 | 379.56 | 25.30 | 902.22 | 376.73 | 1278.95 | 104.26 | 0.0866 | 612 | 1076 | 1335 |

| 380 | 26 | 7 | 4.00 | 3.10 | 326.73 | 52.83 | 379.56 | 25.30 | 902.22 | 376.73 | 1278.95 | 104.26 | 0.0866 | 612 | 1076 | 1335 |

| 480 | 26 | 7 | 4.50 | 3.50 | 413.51 | 67.35 | 480.86 | 28.50 | 1141.87 | 480.23 | 1622.10 | 132.42 | 0.0684 | 704 | 1253 | 1559 |

| 480 | 26 | 7 | 4.50 | 3.50 | 413.51 | 67.35 | 480.86 | 28.50 | 1141.87 | 480.23 | 1622.10 | 132.42 | 0.0684 | 704 | 1253 | 1559 |

| 520 | 45 | 7 | 3.70 | 2.47 | 483.85 | 33.54 | 517.39 | 29.61 | 1337.00 | 239.17 | 1576.17 | 113.10 | 0.0597 | 748 | 1336 | 1665 |

| 520 | 45 | 7 | 3.70 | 2.47 | 483.85 | 33.54 | 517.39 | 29.61 | 1337.00 | 239.17 | 1576.17 | 113.10 | 0.0597 | 748 | 1336 | 1665 |

| 590 | 54 | 7 | 3.50 | 3.50 | 519.54 | 67.35 | 586.89 | 31.50 | 1437.04 | 480.23 | 1917.27 | 150.84 | 0.0549 | 790 | 1419 | 1771 |

| 600 | 54 | 7 | 3.53 | 3.53 | 528.49 | 68.51 | 596.99 | 31.77 | 1461.78 | 488.50 | 1950.28 | 152.20 | 0.0540 | 797 | 1434 | 1791 |

| 630 | 54 | 19 | 3.63 | 2.18 | 558.85 | 70.92 | 629.77 | 32.68 | 1545.78 | 507.40 | 2053.17 | 163.93 | 0.0511 | 824 | 1486 | 1857 |

| 690 | 54 | 7 | 3.80 | 3.80 | 612.42 | 79.39 | 691.81 | 34.20 | 1693.95 | 566.08 | 2260.03 | 176.38 | 0.0466 | 869 | 1576 | 1972 |

| 710 | 54 | 19 | 3.85 | 2.31 | 628.65 | 79.63 | 708.27 | 34.65 | 1738.82 | 569.72 | 2308.54 | 182.37 | 0.0454 | 883 | 1602 | 2006 |

| 730 | 45 | 7 | 4.40 | 2.90 | 684.24 | 46.24 | 730.48 | 35.10 | 1890.75 | 329.69 | 2220.44 | 155.82 | 0.0423 | 914 | 1663 | 2084 |

| 770 | 54 | 7 | 4.00 | 4.00 | 678.59 | 87.96 | 766.55 | 36.00 | 1876.95 | 627.24 | 2504.19 | 193.40 | 0.0421 | 922 | 1682 | 2108 |

| 800 | 54 | 19 | 4.09 | 2.45 | 709.47 | 89.57 | 799.04 | 36.79 | 1962.37 | 640.86 | 2603.23 | 205.51 | 0.0403 | 946 | 1729 | 2169 |

| 900 | 54 | 19 | 4.34 | 2.61 | 798.85 | 101.65 | 900.50 | 39.09 | 2209.60 | 727.30 | 2936.90 | 230.40 | 0.0357 | 1014 | 1868 | 2348 |

SUPER THERMAL RESISTANT ALUMINUM ALLOY CONDUCTOR, ALUMINUM CLAD INVAR REINFORCED (STACIR/TW)

| Conductor Size | Cross-Sectional Area | Stranding | Diameter of Complete Conductor | Weight | Rated Strength | DC

Resistance @ 20°C |

Current Capacity | |||||||||

| STAL | Invar | Total | No. of STAL

Wires |

No. of

STAL Layers |

No. of Invar

Wires |

Dia. of Invar

Wires |

STAL | Invar | Total | |||||||

| @ 85°C | @ 150°C | @ 210°C | ||||||||||||||

| (mm²) | (mm²) | (mm²) | (mm²) | (No.) | (No.) | (No.) | (mm) | (mm) | (Kg/Km) | (Kg/Km) | (Kg/Km) | (KN) | (Ω/Km) | (Ampere) | (Ampere) | (Ampere) |

| 320 | 322.26 | 52.49 | 374.75 | 20 | 2 | 7 | 3.09 | 22.88 | 888.49 | 374.31 | 1262.80 | 100.95 | 0.0876 | 596 | 1039 | 1287 |

| 340 | 336.85 | 54.90 | 391.75 | 20 | 2 | 7 | 3.16 | 23.38 | 928.73 | 391.46 | 1320.19 | 105.55 | 0.0838 | 612 | 1069 | 1324 |

| 390 | 389.25 | 50.81 | 440.06 | 20 | 2 | 7 | 3.04 | 24.72 | 1073.18 | 362.29 | 1435.47 | 109.47 | 0.0731 | 662 | 1163 | 1442 |

| 405 | 402.83 | 52.15 | 454.98 | 20 | 2 | 7 | 3.08 | 25.14 | 1110.62 | 371.89 | 1482.51 | 112.86 | 0.0706 | 676 | 1189 | 1475 |

| 480 | 479.69 | 47.20 | 526.89 | 35 | 3 | 7 | 2.93 | 26.98 | 1329.03 | 336.55 | 1665.58 | 123.00 | 0.0600 | 733 | 1298 | 1613 |

| 490 | 489.57 | 63.55 | 553.13 | 24 | 2 | 7 | 3.40 | 27.70 | 1349.78 | 453.18 | 1802.96 | 136.19 | 0.0581 | 759 | 1347 | 1676 |

| 525 | 523.67 | 26.85 | 550.53 | 30 | 3 | 7 | 2.21 | 27.50 | 1450.88 | 191.47 | 1642.35 | 107.39 | 0.0556 | 763 | 1354 | 1685 |

| 590 | 586.76 | 41.28 | 628.03 | 33 | 3 | 7 | 2.74 | 29.40 | 1625.66 | 294.31 | 1919.97 | 131.16 | 0.0494 | 820 | 1464 | 1825 |

| 625 | 625.07 | 79.63 | 704.69 | 38 | 3 | 19 | 2.31 | 31.32 | 1731.79 | 569.72 | 2301.51 | 177.43 | 0.0458 | 862 | 1549 | 1935 |

| 640 | 636.97 | 44.03 | 681.00 | 35 | 3 | 7 | 2.83 | 30.60 | 1764.78 | 313.97 | 2078.75 | 141.60 | 0.0455 | 860 | 1542 | 1925 |

| 680 | 676.24 | 85.95 | 762.20 | 39 | 3 | 19 | 2.40 | 32.58 | 1873.58 | 614.97 | 2488.55 | 191.75 | 0.0423 | 903 | 1630 | 2037 |

| 690 | 688.96 | 47.52 | 736.48 | 36 | 3 | 7 | 2.94 | 31.80 | 1908.82 | 338.85 | 2247.67 | 151.77 | 0.0421 | 899 | 1620 | 2024 |

| 725 | 725.09 | 91.78 | 816.87 | 39 | 3 | 19 | 2.48 | 33.72 | 2008.91 | 656.66 | 2665.57 | 205.21 | 0.0395 | 940 | 1703 | 2131 |

| 730 | 726.41 | 91.78 | 818.19 | 39 | 3 | 19 | 2.48 | 33.75 | 2012.56 | 656.66 | 2669.22 | 205.41 | 0.0394 | 941 | 1705 | 2134 |

| 740 | 737.40 | 51.14 | 788.54 | 36 | 3 | 7 | 3.05 | 32.92 | 2043.02 | 364.68 | 2407.70 | 162.72 | 0.0393 | 936 | 1692 | 2117 |

| 780 | 776.92 | 98.56 | 875.49 | 39 | 3 | 19 | 2.57 | 34.90 | 2152.52 | 705.18 | 2857.70 | 218.33 | 0.0368 | 979 | 1780 | 2231 |

| 790 | 789.13 | 54.55 | 843.69 | 36 | 3 | 7 | 3.15 | 34.05 | 2186.36 | 388.98 | 2575.34 | 173.95 | 0.0367 | 973 | 1767 | 2213 |

| 820 | 821.87 | 108.79 | 930.65 | 39 | 3 | 19 | 2.70 | 36.00 | 2277.05 | 778.33 | 3055.38 | 235.56 | 0.0348 | 1012 | 1847 | 2316 |

| 840 | 839.80 | 58.07 | 897.88 | 36 | 3 | 7 | 3.25 | 35.14 | 2326.74 | 414.07 | 2740.81 | 185.14 | 0.0345 | 1008 | 1837 | 2304 |

| 880 | 876.90 | 111.22 | 988.11 | 42 | 3 | 19 | 2.73 | 37.10 | 2429.50 | 795.72 | 3225.22 | 246.40 | 0.0326 | 1050 | 1923 | 2414 |

| 890 | 891.08 | 61.70 | 952.78 | 42 | 3 | 7 | 3.35 | 36.18 | 2468.81 | 439.95 | 2908.76 | 195.42 | 0.0325 | 1043 | 1907 | 2394 |

| 900 | 901.93 | 73.54 | 975.47 | 42 | 3 | 19 | 2.22 | 36.70 | 2498.85 | 526.19 | 3025.04 | 213.21 | 0.0320 | 1054 | 1931 | 2425 |

| 980 | 976.36 | 123.77 | 1100.13 | 42 | 3 | 19 | 2.88 | 39.12 | 2705.08 | 885.56 | 3590.64 | 274.28 | 0.0293 | 1115 | 2056 | 2587 |

| 990 | 987.86 | 68.90 | 1056.76 | 42 | 3 | 7 | 3.54 | 38.10 | 2736.95 | 491.27 | 3228.22 | 217.12 | 0.0293 | 1105 | 2035 | 2560 |

LS Cable & System Standard STAl Wire

| Standard Diameter

(mm) |

Tolerance of Dia.

(mm) |

Tensile Strength (kgf/mm2) |

Elongation on 250mm(%)

Min |

Reference | |||||

| Cross- sectional Area

(mm2) |

Weight

(kg/km) |

breaking Load (kgf) | DC

Resistance at 20℃ (Ω/km) |

||||||

|

Min. |

Avg |

||||||||

| Min. | Avg (Min.) | ||||||||

| 2.6 | ±0.03 | 17.2 | 18.3 | 1.5 | 5.309 | 14.33 | 91.3 | 97.2 | 5.41 |

| 3.2 | ±0.04 | 16.5 | 17.6 | 1.7 | 8.042 | 21.71 | 133 | 142 | 3.57 |

| 3.38 | ±0.04 | 16.5 | 17.6 | 1.7 | 8.973 | 24.23 | 148 | 158 | 3.20 |

| 3.7 | ±0.04 | 16.5 | 17.2 | 1.8 | 10.75 | 29.03 | 177 | 185 | 2.67 |

| 4.0 | ±0.04 | 16.2 | 16.9 | 1.9 | 12.57 | 33.94 | 204 | 212 | 2.29 |

| 4.5 | ±0.04 | 16.2 | 16.9 | 2.0 | 15.90 | 42.93 | 258 | 269 | 1.81 |

Aluminum-clad INVAR Wire

| Standard Diameter

(mm) |

Tolerance of Dia.

(mm) |

Tensile Strength

(kgf/mm2) |

Elongation Min.

(%) |

No. of Twists

(Nos.) |

Conductivity

(%IACS) |

Properties of Aluminum | Reference | |||||||

| Thickness

(mm) |

Wrapping | Aluminum

Thickness (mm) |

Cross-

sectional Area (mm2) |

Weight

(kg/km) |

breaking

Load (kgf) |

Coefficient of Linear Expainsion | Modulus

of Elasticity (kgf/mm2) |

|||||||

| 15℃~230℃

(x10-6/℃) |

230℃~290℃

(x10-6/℃) |

|||||||||||||

| 2.47 | ±0.05 | 110 | 1.5 | 20 | 14 | 0.06 | No

separation between aluminum and invar core or no breakage |

0.15 | 4.790 | 34.02 | 527 | 3.7 | 10.8 | 15,500 |

| 2.6 | ±0.05 | 110 | 1.5 | 20 | 14 | 0.06 | 0.15 | 5.309 | 37.69 | 584 | 3.7 | 10.8 | 15,500 | |

| 3.1 | ±0.06 | 110 | 1.5 | 20 | 14 | 0.07 | 0.17 | 7.548 | 53.48 | 830 | 3.7 | 10.8 | 15,500 | |

| 3.2 | ±0.06 | 110 | 1.5 | 20 | 14 | 0.07 | 0.17 | 8.042 | 57.10 | 885 | 3.7 | 10.8 | 15,500 | |

| 3.38 | ±0.07 | 110 | 1.5 | 20 | 14 | 0.08 | 0.18 | 8.973 | 63.71 | 987 | 3.7 | 10.8 | 15,500 | |

| 3.5 | ±0.07 | 110 | 1.5 | 20 | 14 | 0.08 | 0.18 | 9.621 | 68.31 | 1.060 | 3.7 | 10.8 | 15,500 | |

High Tensile Strength Aluminum-clad INVAR Wire

| Standard Diameter

(mm) |

Tolerance of Dia.

(mm) |

Tensile Strength

(kgf/mm2) |

Elongation Min.

(%) |

No. of Tweists

(Nos.) |

Conductivity

(%IACS) |

Properties of Aluminum | Reference | |||||||

| Thickness

(mm) |

Wrapping | Aluminum Thickness

(mm) |

Cross- sectional Area (mm2) | Weight

(kg/km) |

breaking Load

(kgf) |

Coefficient of Linear Expainsion | Modulus of Elasticity

(kgf/mm2) |

|||||||

| 15℃~230℃ (x10-6/℃) | 230℃~290℃ (x10-6/℃) | |||||||||||||

| 2.47 | ±0.05 | 125 | 1.5 | 20 | 14 | 0.06 | No separation between aluminum and invar core or no breakage | 0.15 | 4.790 | 34.02 | 599 | 3.7 | 10.8 | 15,500 |

| 2.6 | ±0.05 | 120 | 1.5 | 20 | 14 | 0.06 | 0.15 | 5.309 | 37.69 | 637 | 3.7 | 10.8 | 15,500 | |

| 3.1 | ±0.06 | 120 | 1.5 | 20 | 14 | 0.07 | 0.17 | 7.548 | 53.48 | 906 | 3.7 | 10.8 | 15,500 | |

| 3.2 | ±0.06 | 120 | 1.5 | 20 | 14 | 0.07 | 0.17 | 8.042 | 57.10 | 965 | 3.7 | 10.8 | 15,500 | |

| 3.38 | ±0.07 | 120 | 1.5 | 20 | 14 | 0.08 | 0.18 | 8.973 | 63.71 | 1.077 | 3.7 | 10.8 | 15,500 | |

| 3.5 | ±0.07 | 120 | 1.5 | 20 | 14 | 0.08 | 0.18 | 9.621 | 68.31 | 1.155 | 3.7 | 10.8 | 15,500 | |

LS Cable & System Standard STACIR / AW

| Conductor Size

(mm2) |

Stranding (Nos./mm) | Min. Breaking Load

(kgf) |

Overall Diameter

(mm) |

Reference | ||||||||||

| Cross-sectional Area (mm2) | Weight (kg/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion

(10-6/℃) |

DC

Resistance at 20℃ (Ω/km) |

Current Carrying Capacity (A) | |||||||||

| STAl | INVAR | STAl | INVAR | Total | STAl | INVAR | Total | |||||||

| 160 | 30/2.6 | 7/2.6 | 6,140 | 18.20 | 159.30 | 37.16 | 196.46 | 441.7 | 265.2 | 706.9 | 8,040 | 16.0 | 0.1745 | 909 |

| 240 | 30/3.2 | 7/3.2 | 9,170 | 22.40 | 241.30 | 56.29 | 297.59 | 669.1 | 401.7 | 1070.8 | 8,040 | 16.0 | 0.1159 | 1,203 |

| 330 | 26/4.0 | 7/3.1 | 10,000 | 25.30 | 326.80 | 52.84 | 379.64 | 905.1 | 377.0 | 1282.1 | 7,580 | 17.5 | 0.0869 | 1,452 |

| 410 | 26/4.5 | 7/3.5 | 12,720 | 28.50 | 413.40 | 67.35 | 480.75 | 1145.5 | 480.6 | 1626.1 | 7,590 | 17.5 | 0.0686 | 1,708 |

| 480 (Rail) | 45/3.7 | 7/2.47 | 10,500 | 29.61 | 483.84 | 33.54 | 517.38 | 1340.7 | 239.3 | 1580.0 | 6,900 | 20.0 | 0.0600 | 1,812 |

| 480 (Cardinal) | 54/3.38 | 7/3.38 | 13,280 | 30.42 | 484.52 | 62.81 | 547.33 | 1343.5 | 452.2 | 1795.7 | 7,470 | 18.3 | 0.0591 | 1,846 |

Hi-STACIR/AW

| Conductor Size

(mm2) |

Stranding (Nos./mm) | Min. Breaking Load

(kgf) |

Overall Diameter

(mm) |

Reference | ||||||||||

| Cross-sectional Area (mm2) | Weight (kg/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion

(10-6/℃) |

DC

Resistance at 20℃ (Ω/km) |

Current Carrying Capacity (A) | |||||||||

| STAl | INVAR | STAl | INVAR | Total | STAl | INVAR | Total | |||||||

| 160 | 30/2.6 | 7/2.6 | 6,500 | 18.20 | 159.30 | 37.16 | 196.46 | 441.7 | 265.2 | 706.9 | 8,040 | 16.0 | 0.1745 | 909 |

| 240 | 30/3.2 | 7/3.2 | 9,700 | 22.40 | 241.30 | 56.29 | 297.59 | 669.1 | 401.7 | 1070.8 | 8,040 | 16.0 | 0.1159 | 1,203 |

| 330 | 26/4.0 | 7/3.1 | 10,500 | 25.30 | 326.80 | 52.84 | 379.64 | 905.1 | 377.0 | 1282.1 | 7,580 | 17.5 | 0.0869 | 1,452 |

| 410 | 26/4.5 | 7/3.5 | 13,300 | 28.50 | 413.40 | 67.35 | 480.75 | 1145.5 | 480.6 | 1626.1 | 7,590 | 17.5 | 0.0686 | 1,708 |

| 480 (Rail) | 45/3.7 | 7/2.47 | 11,000 | 29.61 | 483.84 | 33.54 | 517.38 | 1340.7 | 239.3 | 1580.0 | 6,900 | 20.0 | 0.0600 | 1,812 |

| 480 (Cardinal) | 54/3.38 | 7/3.38 | 13,800 | 30.42 | 484.52 | 62.81 | 547.33 | 1343.5 | 452.2 | 1795.7 | 7,470 | 18.3 | 0.0591 | 1,846 |

Comparison with Conventional ACSR

| Conductor Size

(mm2) |

Stranding

(Nos./mm) |

Weight

(kg/km) |

Overall Diameter

(mm) |

Breaking Load

(kgf) |

DC

Resistant at 20℃ (Ω/km) |

Modulus of Elasticity ①

(kgf/mm2) |

Coefficient of Linear Expansion ②

(x10-6/℃) |

Continuous Current Capacity (A) | ||

|

160 |

ACSR |

HAl | 30/2.6 |

732.8 |

18.2 |

6,990 |

0.182 |

9,080 |

18.0 |

454 (90℃) |

| St | 7/2.6 | |||||||||

|

Hi-STACIR/AW |

STAl | 30/2.6 |

706.9 |

18.2 |

6,500 |

0.1745 |

8,040 (15,500) |

16.0 (3.7) |

909 (210℃) | |

| INVAR | 7/2.6 | |||||||||

|

240 |

ACSR | HAl | 30/3.2 | 1,110 | 22.4 | 10,210 | 0.139 | 9,080 | 18.0 | 593 (90℃) |

| St | 7/3.2 | |||||||||

|

Hi-STACIR/AW |

STAl | 30/3.2 |

1,070.8 |

22.4 |

9,700 |

0.1159 |

8,040 (15,500) |

16.0 (3.7) |

1,203 (210℃) | |

| INVAR | 7/3.2 | |||||||||

|

330 |

ACSR | HAl | 26/4.0 | 1,260 | 25.3 | 10,950 | 0.0873 | 8,360 | 19.0 | 714 (90℃) |

| St | 7/3.1 | |||||||||

| Hi-STACIR/AW | STAl | 26/4.0 | 1,282.1 | 25.3 | 10,500 | 0.0869 | 7,580 (15,500) | 17.5 (3.7) | 1,452 (210℃) | |

| INVAR | 7/3.1 | |||||||||

|

410 |

ACSR | HAl | 26/4.5 | 1,673 | 28.5 | 13,890 | 0.0702 | 8,360 | 19.0 | 829 (90℃) |

| St | 7/3.5 | |||||||||

|

Hi-STACIR/AW |

STAl | 26/4.5 |

1,626.1 |

28.5 |

13,300 |

0.0686 |

7,590 (15,500) |

17.5 (3.7) |

1,708 (210℃) | |

| INVAR | 7/3.5 | |||||||||

|

480 (Rail) |

ACSR | HAl | 45/3.7 | 1,599 | 29.61 | 11,800 | 0.05994 | 7,250 | 20.8 | 891 (90℃) |

| St | 7/2.47 | |||||||||

|

Hi-STACIR/AW |

STAl | 45/3.7 |

1,580 |

29.61 |

11,000 |

0.0600 |

6,900 (15,500) |

20.0 (3.7) |

1,812 (210℃) | |

| INVAR | 7/2.47 | |||||||||

|

480 (Cardinal) |

ACSR | HAl | 54/3.38 | 1,836 | 30.42 | 15,300 | 0.0599 | 7,990 | 19.5 | 899 (90℃) |

| St | 7/3.38 | |||||||||

| Hi-STACIR/AW | STAl | 54/3.38 | 1,795.7 | 30.42 | 13,800 | 0.0591 | 7,470 (15,500) | 18.3 (3.7) | 1,846 (210℃) | |

| INVAR | 7/3.38 | |||||||||

Case Video

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

Originated in 2004, Hengwang Cable specializes in manufacturing a comprehensive range of electric wires and cables with rated voltages from 300V to 110kV.

our products

NEED HELP

Contact Info

- Email: inquiry@hengwangcable.com

- Phone: +86 13838542578

- WeChat: +86 13838542578

- WhatsApp: +86 13838542578

- Address: Northeast of Xinghu Road, Huji Town, Huimin County, Binzhou City, Shandong Province

© Copyright 2025 by Shandong Hengwang Cable Co., Ltd. All Rights Reserved.