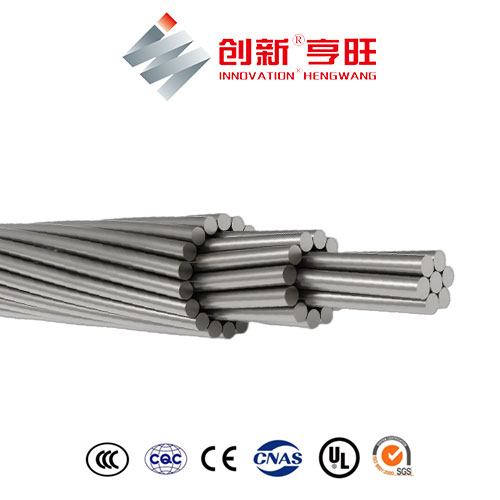

All Aluminum Alloy Conductors (AAAC)

Minimum Order Quantity: 2KM;

Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Shipping: Shipping fee and delivery date to be negotiated. Chat with supplier now for more details;

Secure Payments: Every payment you make is secured with strict SSL encryption and PCI DSS data protection protocols;

Delivery Terms: FOB, CFR, EXW, FAS, DDP;

Payment Currency: USD, EUR, CAD, AUD, GBP, CNY

Share:

Product Description

All Aluminum Alloy Conductors (AAAC)

Overhead Transmission AAAC Bare Conductors

All Aluminum Alloy Conductors Application

AAAC is mainly used as bare overhead transmission cable and as primary and secondary distribution cable. It is also suitable for laying across basins, rivers and valleys where special geographical features exist.

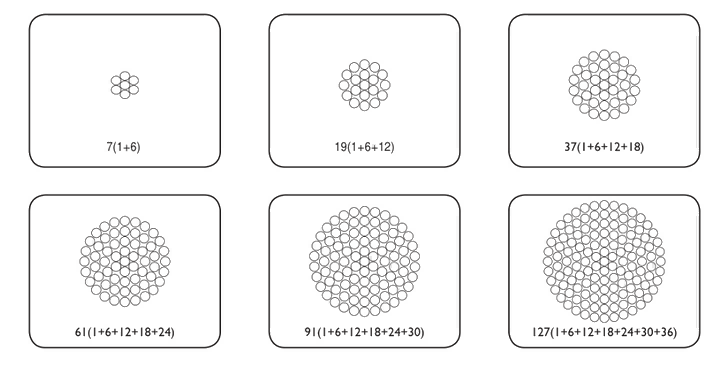

All Aluminum Alloy Conductors Construction

AAAC cable consists of aluminum alloy wires. The aluminum alloy wires are concentrically stranded.

Conductors to all other recognized specifications can also be supplied. The alloys referred to have higher strength but lower conductivity than pure aluminium.

Being lighter, alloy conductors can sometimes be used to advantage in place of the more conventional ACSR; Having lower breaking loads than the later, their use becomes particularly favorable when ice and wind loadings are low.

All Aluminum Alloy Conductors Characteristics

Electrical Properties

- Density at 20℃: 2.703 kg/dm3

- Temperature Coefficient at 20°C: 0.00360 (°C)

- Resistivity at 20°C: 0.03260Ω•mm2/m

- Coefficient of linear expansion: 23 x10-6 (°C)

Service Conditions

- Seismic Acceleration: 0.12 – 0.05g

- Ambient Temperature: -5°C – 50°C

- Wind Pressure: 80 – 130kg/m2

- Isokeraunic Level: 10 – 18

- Relative Humidity: 5 – 100%

All Aluminum Alloy Conductors Specifications

AAAC-All Aluminum Alloy Conductors IEC61089

| Code Number | A2 Conductor | A3 Conductor | Max.D.C. Resistance of Conductor at 20°C | ||||||||

| Number of Wires | Diameter of Wires | Diameter of Conductor | Approx. Weight | Rated Strength | Number of Wires | Diameter of Wires | Diameter of Conductor | Approx. Weight | Rated Strength | ||

|

mm²

|

– | mm | mm | kg/km | daN | – | mm | mm | kg/km | daN | Ω/km |

| 16 | 7 | 1.83 | 5.49 | 50.4 | 5.43 | 50.8 | 6.04 | 50.8 | 6.04 | 1.7896 | |

| 25 | 7 | 2.29 | 6.87 | 78.7 | 8.49 | 1.1453 | 79.5 | 9.44 | 79.5 | 9.44 | 1.1453 |

| 40 | 7 | 2.89 | 8.67 | 125.9 | 13.58 | 0.7158 | 127.1 | 15.1 | 127.1 | 15.1 | 0.7158 |

| 63 | 7 | 3.63 | 10.8 | 198.3 | 21.39 | 0.4545 | 200.2 | 23.06 | 200.2 | 23.06 | 0.4545 |

| 100 | 19 | 2.78 | 13.9 | 316.3 | 33.95 | 0.2877 | 319.3 | 37.76 | 319.3 | 37.76 | 0.2877 |

| 125 | 19 | 3.10 | 15.5 | 395.4 | 42.44 | 0.2302 | 399.2 | 47.20 | 399.2 | 47.20 | 0.2302 |

| 160 | 19 | 3.51 | 17.55 | 506.1 | 54.32 | 0.1798 | 511.0 | 58.56 | 511.0 | 58.56 | 0.1798 |

| 200 | 19 | 3.93 | 19.65 | 623.7 | 67.91 | 0.1439 | 638.7 | 73.20 | 638.7 | 73.20 | 0.1439 |

| 250 | 19 | 4.39 | 21.95 | 790.8 | 84.68 | 0.1151 | 798.4 | 91.50 | 798.4 | 91.50 | 0.1151 |

| 315 | 37 | 3.53 | 24.71 | 998.9 | 106.95 | 0.0916 | 1008.4 | 115.29 | 1008.4 | 115.29 | 0.0916 |

| 400 | 37 | 3.98 | 27.86 | 1268.4 | 135.81 | 0.0721 | 1280.5 | 146.4o | 1280.5 | 146.4o | 0.0721 |

| 450 | 37 | 4.22 | 29.54 | 1426.9 | 152.79 | 0.0641 | 1440.5 | 164.70 | 1440.5 | 164.70 | 0.0641 |

| 500 | 37 | 4.45 | 31.15 | 1585.5 | 169.76 | 0.0577 | 1600.6 | 183.00 | 1600.6 | 183.00 | 0.0577 |

| 560 | 61 | 3.67 | 33.03 | 1778.4 | 190.14 | 0.0516 | 1795.3 | 204.95 | 1795.3 | 204.95 | 0.0516 |

| 630 | 61 | 3.89 | 35.01 | 2000.7 | 213.90 | 0.0458 | 2019.8 | 230.58 | 2019.8 | 230.58 | 0.0458 |

| 710 | 61 | 4.13 | 37.17 | 2254.8 | 241.07 | 0.0407 | 2276.2 | 259.86 | 2276.2 | 259.86 | 0.0407 |

| 800 | 61 | 4.38 | 39.42 | 2540.6 | 271.62 | 0.0361 | 2564.8 | 282.80 | 2564.8 | 282.80 | 0.0361 |

| 900 | 91 | 3.81 | 41.91 | 2861.1 | 305.58 | 0.0632 | 2888.3 | 329.40 | 2888.3 | 329.40 | 0.0321 |

| 1000 | 91 | 4.01 | 44.11 | 3179.0 | 339.53 | 0.0289 | 3209.3 | 366.00 | 3209.3 | 366.00 | 0.0289 |

| 1120 | 91 | 4.25 | 46.75 | 3560.5 | 380.27 | 0.0258 | 3594.4 | 409.92 | 3594.4 | 409.92 | 0 0258 |

All Aluminum Alloy Conductors IEC 61089 A3

| IEC Spec All Aluminum Alloy Conductors Type A3 |

|||||||

| Code Name |

Area Actual |

Equivalent Copper Area |

Stranding | Overall Diameter |

Weight | Rated Strength |

Maximum DC Resistance at 20℃ |

| mm2 | mm2 | No/mm | mm | kg/km | kN | Ω /km | |

| 16 | 18.6 | 9.8 | 7/1.84 | 5.52 | 50.8 | 6.04 | 1.7896 |

| 25 | 29 | 15.2 | 7/2.30 | 6.9 | 79.5 | 9.44 | 1.1453 |

| 40 | 46.5 | 24.4 | 7/2.91 | 8.73 | 127.1 | 15.1 | 0.7158 |

| 63 | 73.2 | 38.4 | 7/3.65 | 10.95 | 200.2 | 23.06 | 0.4545 |

| 100 | 116 | 61 | 19/2.79 | 14 | 319.3 | 37.76 | 0.2877 |

| 125 | 145 | 76 | 19/3.12 | 15.6 | 399.2 | 47.2 | 0.2302 |

| 160 | 186 | 98 | 19/3.53 | 17.7 | 511 | 58.56 | 0.1798 |

| 200 | 232 | 122 | 19/3.95 | 19.8 | 638.7 | 73.2 | 0.1439 |

| 250 | 290 | 152 | 19/4.41 | 22.1 | 798.4 | 91.5 | 0.1151 |

| 315 | 366 | 192 | 37/3.55 | 24.9 | 1008.4 | 115.29 | 0.0916 |

| 400 | 465 | 244 | 37/4.00 | 28 | 1280.5 | 146.4 | 0.0721 |

| 450 | 523 | 275 | 37/4.24 | 29.7 | 1440.5 | 164.7 | 0.0641 |

| 500 | 581 | 305 | 37/4.47 | 31.3 | 1600.6 | 183 | 0.0577 |

| 560 | 651 | 342 | 61/3.69 | 33.2 | 1795.3 | 204.96 | 0.0516 |

| 630 | 732 | 384 | 61/3.91 | 35.2 | 2019.8 | 230.58 | 0.0458 |

| 710 | 825 | 433 | 61/4.15 | 37.4 | 2276.2 | 259.86 | 0.0407 |

| 800 | 930 | 488 | 61/4.40 | 39.6 | 2564.8 | 292.8 | 0.0361 |

| 900 | 1046 | 549 | 91/3.83 | 42.1 | 2888.3 | 329.4 | 0.0321 |

| 1000 | 1162 | 610 | 91/4.03 | 44.3 | 3209.3 | 366 | 0.0289 |

| 1120 | 1301 | 683 | 91/4.27 | 47 | 3594.5 | 409.92 | 0.0258 |

AAAC-All Aluminum Alloy Conductors BS EN 50183

| Code | Stranding | Nominal Area | Sectional Area | Overall Diameter | Weight | Rated Strength | Electrical Resistance | Current Rating* |

| No.×mm | mm^2 | mm^2 | mm | kg/km | KN | Ω/Km | A | |

| Box | 7/1.85 | 15 | 18.8 | 5.55 | 51.4 | 5.55 | 1.748 | 87 |

| Acacia | 7/2.08 | 20 | 23.8 | 6.24 | 64.9 | 7.02 | 1.3828 | 101 |

| Almond | 7/2.34 | 25 | 30.1 | 7.02 | 82.2 | 8.88 | 1.0926 | 116 |

| Cedar | 7/2.54 | 30 | 35.5 | 7.62 | 96.8 | 10.46 | 0.9273 | 129 |

| Deodar | 7/2.77 | 35 | 42.2 | 8.31 | 115.2 | 12.44 | 0.7797 | 143 |

| Fir | 7/2.95 | 40 | 47.8 | 8.85 | 130.6 | 14.11 | 0.6875 | 155 |

| Hazel | 7/3.30 | 50 | 59.9 | 9.9 | 163.4 | 17.66 | 0.5494 | 178 |

| Pine | 7/3.61 | 60 | 71.6 | 10.83 | 195.6 | 21.14 | 0.4591 | 199 |

| Holly | 7/3.91 | 70 | 84.1 | 11.73 | 229.5 | 24.79 | 0.3913 | 219 |

| Willow | 7/4.04 | 75 | 89.7 | 12.12 | 245 | 26.47 | 0.3665 | 228 |

| – | 7/4.19 | 80 | 96.52 | 12.57 | 264 | 27.17 | 0.3411 | 245 |

| – | 7/4.44 | 90 | 108.0 | 13.32 | 298 | 30.65 | 0.3023 | 260 |

| Oak | 7/4.65 | 80 | 118.9 | 13.95 | 324.5 | 35.07 | 0.2767 | 272 |

| – | 19/2.82 | 100 | 118.70 | 14.1 | 326 | 33.42 | 0.2787 | 290 |

| Mulberry | 19/3.18 | 125 | 150.9 | 15.9 | 414.3 | 44.52 | 0.2192 | 314 |

| Ash | 19/3.48 | 150 | 180.7 | 17.4 | 496.1 | 53.31 | 0.183 | 351 |

| Elm | 19/3.76 | 175 | 211 | 18.8 | 579.2 | 62.24 | 0.1568 | 386 |

| Poplar | 37/2.87 | 200 | 239.4 | 20.09 | 659.4 | 70.61 | 0.1387 | 416 |

| – | 37/3.05 | 225 | 270.30 | 21.35 | 744 | 76.08 | 0.1227 | 448 |

| Sycamore | 37/3.23 | 250 | 303.2 | 22.61 | 835.2 | 89.4 | 0.1095 | 480 |

| Upas | 37/3.53 | 300 | 362.1 | 24.71 | 997.5 | 106.82 | 0.0917 | 535 |

| Walnut | 37/3.81 | 350 | 421.80 | 26.67 | 1162 | 118.72 | 0.07860 | 584 |

| Yew | 37/4.06 | 400 | 479 | 28.42 | 1319.6 | 141.31 | 0.0693 | 633 |

| Totara | 37/4.14 | 425 | 498.1 | 28.98 | 1372.1 | 146.93 | 0.0666 | 648 |

| Rubus | 61/3.50 | 500 | 586.9 | 31.5 | 1622 | 173.13 | 0.0567 | 714 |

| Sorbus | 61/3.71 | 600 | 659.4 | 33.39 | 1822.5 | 194.53 | 0.0505 | 764 |

| Araucaria | 61/4.14 | 700 | 821.1 | 37.26 | 2269.4 | 242.24 | 0.0406 | 868 |

| Redwood | 61/4.56 | 800 | 996.2 | 41.04 | 2753.2 | 293.88 | 0.0334 | 970 |

AAAC-All Aluminum Alloy Conductors NFC 34 125

| name | name | actual section | no. of wire | wire diameter | conducto diameter | conductor weight appr. | calc. breaking force | calc.conductor resistance |

| NF-C 34125 | EN 50182 | mm² | mm | mm | kg/km | kN | Ohm/km | |

| ASTER 22 | 22-AL4 | 22,0 | 7 | 2,00 | 6,00 | 60,0 | 7,15 | 1,498 |

| ASTER 34,4 | 34-AL4 | 34,4 | 7 | 2,50 | 7,50 | 93,5 | 11,17 | 0,959 |

| ASTER 54,6 | 55-AL4 | 54,6 | 7 | 3,15 | 9,45 | 148,9 | 17,73 | 0,604 |

| ASTER 75,5 | 76-AL4 | 75,5 | 19 | 2,25 | 11,3 | 207,4 | 24,55 | 0,438 |

| ASTER 117 | 117-AL4 | 117,0 | 19 | 2,80 | 14,0 | 321,2 | 38,02 | 0,283 |

| ASTER 148 | 148-AL4 | 148,1 | 19 | 3,15 | 15,8 | 406,6 | 48,12 | 0,223 |

| ASTER 181,6 | 182-AL4 | 181,6 | 37 | 2,50 | 17,5 | 500,3 | 59,03 | 0,183 |

| ASTER 228 | 228-AL4 | 227,8 | 37 | 2,80 | 19,6 | 627,6 | 74,04 | 0,146 |

| ASTER 288 | 288-AL4 | 288,3 | 37 | 3,15 | 22,1 | 794,3 | 93,71 | 0,115 |

| ASTER 366 | 366-AL4 | 366,2 | 37 | 3,55 | 24,9 | 1.008,9 | 115,36 | 0,090 |

| ASTER 570 | 570-AL4 | 570,2 | 61 | 3,45 | 31,1 | 1.576,0 | 185,33 | 0,058 |

| ASTER 851 | 851-AL4 | 850,7 | 91 | 3,45 | 38,0 | 2.360,7 | 276,47 | 0,039 |

| ASTER 1144 | 1144-AL4 | 1.143,5 | 91 | 4,00 | 44,0 | 3.173,4 | 360,22 | 0,029 |

| ASTER 1600 | 1600-AL4 | 1.595,9 | 127 | 4,00 | 52,0 | 4.427,5 | 502,72 | 0,021 |

AAAC-All Aluminum Alloy Conductors ASTM B 399

| Conductor size | No./Diameter of single wire | Approximate overall diameter of cable mm |

Approximate weight of cable kg/km |

Nominal Breaking Load kN |

Maximum DC Resistance at 20℃ Ω/km |

|

| AWG or MCM | mm2 | |||||

| 6 | 13.3 | 7/1.55 | 4.67 | 36.89 | 4.22 | 2.5199 |

| 4 | 21.14 | 7/1.96 | 5.89 | 57.89 | 6.71 | 1.586 |

| 2 | 33.65 | 7/2.47 | 7.42 | 92.14 | 10.69 | 0.9987 |

| 1/0 | 53.49 | 7/3.12 | 9.35 | 146.5 | 16.98 | 0.6259 |

| 2/0 | 67.45 | 7/3.50 | 10.52 | 184.7 | 20.48 | 0.4974 |

| 3/0 | 85 | 7/3.93 | 11.79 | 232.7 | 25.88 | 0.3945 |

| 4/0 | 107.2 | 7/4.42 | 13.26 | 293.7 | 32.67 | 0.3119 |

| 250 | 126.7 | 19/2.91 | 14.58 | 346.9 | 38.97 | 0.2651 |

| 300 | 152.1 | 19/3.19 | 15.89 | 418.6 | 46.77 | 0.2206 |

| 350 | 177.3 | 19/3.46 | 17.25 | 485.5 | 52.26 | 0.1886 |

| 400 | 202.7 | 19/3.69 | 18.44 | 555.1 | 59.76 | 0.1649 |

| 450 | 228 | 19/3.91 | 19.56 | 624.4 | 67.25 | 0.1468 |

| 500 | 253.4 | 19/4.12 | 20.6 | 693.6 | 74.65 | 0.1322 |

| 550 | 278.7 | 37/3.10 | 21.67 | 762.9 | 83.84 | 0.12 |

| 600 | 304 | 37/3.23 | 22.63 | 832 | 91.43 | 0.1105 |

| 650 | 329.4 | 37/3.37 | 23.57 | 909.8 | 99.03 | 0.1015 |

| 700 | 354.5 | 37/3.49 | 24.46 | 910.6 | 101.93 | 0.09464 |

| 750 | 380.2 | 37/3.62 | 25.32 | 1041 | 109.92 | 0.08796 |

| 800 | 405.4 | 37/3.73 | 26.14 | 1109 | 116.91 | 0.08285 |

| 900 | 456.3 | 37/3.96 | 27.74 | 1249 | 131.91 | 0.07351 |

| 1000 | 506.7 | 37/4.18 | 29.24 | 1388 | 145.89 | 0.06597 |

| 1250 | 633.3 | 61/3.63 | 32.67 | 1733 | 179.87 | 0.05306 |

| 1500 | 760 | 61/3.98 | 35.82 | 2081 | 216.84 | 0.04414 |

| 1750 | 886.7 | 61/4.30 | 38.7 | 2429 | 252.82 | 0.03781 |

All Aluminium Alloy Conductors(AAAC) to ASTM B 399 Standard

| Code | Conductor size | No./Diameter of single wire | Approximate overall diameter of cable mm |

Approximate weight of cable kg/km |

Nominal Breaking Load kN |

Maximum DC Resistance at 20℃ Ω/km |

|

| AWG or MCM | mm2 | ||||||

| Akron | 30.58 | 15.48 | 7/1.68 | 5.04 | 42.68 | 4.92 | 2.1556 |

| Alton | 48.69(4) | 24.67 | 7/2.12 | 6.35 | 67.56 | 7.83 | 1.3557 |

| Amas | 77.47(2) | 39.26 | 7/2.67 | 8.02 | 107.5 | 12.5 | 0.8547 |

| Azusa | 123.3(1/0) | 62.46 | 7/3.37 | 10.11 | 171 | 19.79 | 0.5365 |

| Anahelm | 155.4(2/0) | 78.75 | 7/3.78 | 11.35 | 215.16 | 23.98 | 0.4264 |

| Amherst | 195.7(3/0) | 99.2 | 7/4.25 | 12.75 | 271.5 | 30.17 | 0.3373 |

| Altiance | 246.9(4/0) | 125.1 | 7/4.77 | 14.3 | 342.6 | 38.07 | 0.2678 |

| Butte | 312.8 | 158.5 | 19/3.26 | 16.31 | 434 | 48.76 | 0.2112 |

| Canton | 394.5 | 199 | 19/3.66 | 18.31 | 547.4 | 58.96 | 0.1676 |

| Calro | 465.4 | 235.8 | 19/3.98 | 19.89 | 645.7 | 69.55 | 0.1431 |

| Darien | 559.5 | 283.5 | 19/4.36 | 21.79 | 776.3 | 83.55 | 0.1181 |

| Elgin | 652.4 | 330.6 | 19/4.71 | 23.55 | 970.6 | 97.43 | 0.1012 |

| Flint | 740.8 | 375.4 | 37/3.59 | 25.15 | 1028 | 107.93 | 0.08944 |

| Greeley | 927.2 | 469.8 | 37/4.02 | 28.14 | 1287 | 135.91 | 0.07133 |

AAAC-All Aluminum Alloy Conductors DIN 48201

| Aluminium Alloy Conductors (AAAC) DIN 48201 | |||||||

| Code Number | Area. | No.of wires | Diameter | Linear Mass | Rated Tensile strengrh | DC Resistance at 20℃ |

|

| Wire | Cond. | ||||||

| mm 2 | mm 2 | mm | mm | kg/km | daN | Ω/km | |

| 16 | 15.89 | 7 | 1.7 | 5.1 | 43.3 | 444 | 2.091 |

| 25 | 24.25 | 7 | 2.1 | 6.3 | 66.2 | 677 | 1.3703 |

| 35 | 34.36 | 7 | 2.5 | 7.5 | 93.8 | 960 | 0.9669 |

| 50 | 49.48 | 7 | 3 | 9 | 135.1 | 1382 | 0.6714 |

| 50 | 48.35 | 19 | 1.8 | 9 | 132.7 | 1350 | 0.6905 |

| 70 | 65.81 | 19 | 2.1 | 10.5 | 180.7 | 1838 | 0.5073 |

| 95 | 93.27 | 19 | 2.5 | 12.5 | 256 | 2605 | 0.3579 |

| 120 | 116.99 | 19 | 2.8 | 14 | 322 | 3268 | 0.2854 |

| 150 | 147.11 | 37 | 2.25 | 15.8 | 406 | 4109 | 0.2274 |

| 185 | 181.62 | 37 | 2.5 | 17.5 | 500.3 | 5073 | 0.1842 |

| 240 | 242.54 | 61 | 2.25 | 20.3 | 670.3 | 6774 | 0.1383 |

| 300 | 299.43 | 61 | 2.5 | 22.5 | 827 | 8363 | 0.112 |

| 400 | 400.14 | 61 | 2.89 | 26 | 1104 | 11176 | 0.0838 |

| 500 | 499.63 | 61 | 3.23 | 29.1 | 1379 | 13960 | 0.06709 |

| 625 | 626.2 | 91 | 2.96 | 32.6 | 1732 | 17490 | 0.054 |

| 800 | 802.09 | 91 | 3.35 | 36.9 | 2218 | 22402 | 0.0418 |

| 1000 | 999.71 | 91 | 3.74 | 41.1 | 2767 | 27922 | 0.0335 |

AAAC-All Aluminum Alloy Conductors AS 1531

| AAAC 6201- All Aluminium Alloy Conductor | AS 1531 | ||||||

| Code Name | Strands/Wire Diameter | Overall Diameter (Approx) | Calculated Equivalent Aluminium Area | Sectional Area | Approx. Mass |

Calculated Minimum Breaking Load | D.C.Resistence at 20℃ |

| mm | mm | mm2 | mm2 | kg/km | kN | Ω/km | |

| Agate | 7/1.75 | 5.25 | 14.3 | 16.84 | 46 | 4.71 | 1.972 |

| Amethyst | 7/2.25 | 6.75 | 23.7 | 27.83 | 76 | 7.78 | 1.194 |

| Diamond | 7/2.50 | 7.50 | 29.3 | 34.36 | 94 | 9.64 | 0.967 |

| Dolomite | 7/2.75 | 8.25 | 35.4 | 41.58 | 114 | 11.6 | 0.799 |

| Emerald | 7/3.00 | 9.00 | 42.2 | 49.48 | 136 | 13.9 | 0.671 |

| Garnet | 7/3.75 | 11.3 | 65.8 | 77.28 | 211 | 21.7 | 0.43 |

| Jade | 7/4.50 | 13.5 | 94.8 | 111.3 | 304 | 31.2 | 0.298 |

| Jasper | 7/4.75 | 14.3 | 106 | 124.0 | 340 | 34.8 | 0.268 |

| Opal | 19/3.25 | 16.3 | 134 | 157.6 | 433 | 44.2 | 0.212 |

| Patronite | 19/3.50 | 17.5 | 155 | 182.80 | 502 | 51.3 | 0.183 |

| Pearl | 19/3.75 | 18.8 | 178 | 209.8 | 577 | 58.8 | 0.159 |

| Ruby | 37/3.00 | 21.0 | 221 | 261.60 | 720 | 73.5 | 0.128 |

| Ruthenium | 37/3.25 | 22.8 | 260 | 307.00 | 845 | 86.1 | 0.109 |

| Rutile | 19/4.75 | 23.8 | 285 | 336.7 | 925 | 94.4 | 0.09991 |

| Sapphire | 37/3.75 | 26.3 | 345 | 408.50 | 1125 | 115 | 0.0819 |

| Spinel | 61/3.25 | 29.3 | 427 | 506.10 | 1396 | 135 | 0.0662 |

| Tantalum | 61/3.50 | 31.5 | 495 | 586.90 | 1620 | 156 | 0.0572 |

| Topaz | 61/3.75 | 33.8 | 568 | 673.40 | 1858 | 179 | 0.0498 |

| Zircon | 91/4.50 | 49.5 | 1220 | 1447 | 3997 | 384 | 0.0232 |

AAAC-All Aluminum Alloy Conductors IS 398 PART 4

| Name ref. | Conductor cross-section (mm2) |

Stranding (No./mm) |

Nominal overall diameter (mm) |

Approximate weight (kg/km) |

Current Carrying Capacity at 45ºC (Amp) |

| Mole | 15 | 3/2.50 | 5.38 | 40.15 | 65 |

| Squirrel | 22 | 7/2.00 | 6.00 | 60.16 | 105 |

| Weasel | 34 | 7/2.50 | 7.50 | 94.00 | 155 |

| Rabbit | 55 | 7/3.15 | 9.45 | 149.20 | 210 |

| Raccoon | 80 | 7/3.81 | 11.43 | 218.26 | 290 |

| Dog | 100 | 7/4.26 | 12.78 | 272.86 | 325 |

| Dog-up | 125 | 19/2.89 | 14.45 | 342.51 | 360 |

| Coyote | 148 | 19/3.15 | 15.75 | 406.91 | 400 |

| Wolf | 173 | 19/3.40 | 17.0 | 474.02 | 460 |

| Wolf-up | 200 | 19/3.66 | 18.3 | 549.40 | 480 |

| Panther | 232 | 19/3.94 | 19.75 | 636.63 | 520 |

| Panther-up1 | 288 | 37/3.15 | 22.05 | 794.05 | 610 |

| Panther-up2 | 346 | 37/3.45 | 24.15 | 952.56 | 720 |

| Kundah | 400 | 37/3.71 | 25.97 | 1101.63 | 740 |

| Zebra | 465 | 37/4.00 | 28.0 | 1280.50 | 800 |

| Zebra-up | 525 | 61/3.31 | 29.79 | 1448.39 | 875 |

| Moose | 570 | 61/3.45 | 31.05 | 1573.71 | 900 |

| Morkulla | 604 | 61/3.55 | 31.95 | 1666.00 | 920 |

| Moose-up | 642 | 61/3.66 | 32.94 | 1771.36 | 940 |

| Morkulla-up | 695 | 61/3.81 | 34.29 | 1919.13 | 960 |

| Bersimis | 767 | 61/4.00 | 36.0 | 2115.54 | 1000 |

Type Ah GOST 839-80

| Nominal Cross Section | Calculated Cross Section | Number of ires | Conductor Diameter | DC Resistance at 20 | Min. Breaking Load | Conductor Weight |

| mm2 | mm2 | mm | Ω | N | kg/km | |

| 16 | 15.9 | 7 | 5.1 | 1.9037 | 3734 | 43 |

| 25 | 24.9 | 7 | 6.4 | 1.2139 | 5370 | 68 |

| 35 | 34.3 | 7 | 7.5 | 0.8819 | 7389 | 94 |

| 50 | 49.5 | 7 | 9 | 0.6121 | 10662 | 135 |

| 120 | 117 | 19 | 14 | 0.2609 | 25186 | 321 |

| 150 | 148 | 19 | 15.8 | 0.2059 | 31900 | 406 |

| 185 | 182.3 | 19 | 17.5 | 0.1669 | 39386 | 502 |

Type Ankp GOST 839-80

| Nominal Cross Section | Calculated Corss Section | Number of Wires | Conductor Diameter | DC Resistance at 20 | Min. Breaking Load | Conductor Weight | Grease Weight |

| mm2 | mm2 | mm | Ω | N | kg/km | kg/km | |

| 16 | 15.9 | 7 | 5.1 | 1.9037 | 3734 | 43 | 0.5 |

| 25 | 24.9 | 7 | 6.4 | 1.2139 | 5370 | 68 | 0.5 |

| 35 | 34.3 | 7 | 7.5 | 0.8819 | 7389 | 94 | 0.5 |

| 50 | 49.5 | 7 | 9 | 0.6121 | 10662 | 135 | – |

| 120 | 117 | 19 | 14 | 0.2609 | 25186 | 321 | – |

| 150 | 148 | 19 | 15.8 | 0.2059 | 31900 | 406 | – |

| 185 | 182.3 | 19 | 17.5 | 0.1669 |

Case Video

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

Originated in 2004, Hengwang Cable specializes in manufacturing a comprehensive range of electric wires and cables with rated voltages from 300V to 110kV.

our products

NEED HELP

Contact Info

- Email: inquiry@hengwangcable.com

- Phone: +86 13838542578

- WeChat: +86 13838542578

- WhatsApp: +86 13838542578

- Address: Northeast of Xinghu Road, Huji Town, Huimin County, Binzhou City, Shandong Province

© Copyright 2025 by Shandong Hengwang Cable Co., Ltd. All Rights Reserved.