Offshore & Marine Cable

Minimum Order Quantity: 2KM;

Payment Type: T/T, L/C, MoneyGram, Credit Card, Western Union, Cash;

Shipping: Shipping fee and delivery date to be negotiated. Chat with supplier now for more details;

Secure Payments: Every payment you make is secured with strict SSL encryption and PCI DSS data protection protocols;

Delivery Terms: FOB, CFR, EXW, FAS, DDP;

Payment Currency: USD, EUR, CAD, AUD, GBP, CNY

Share:

Product Description

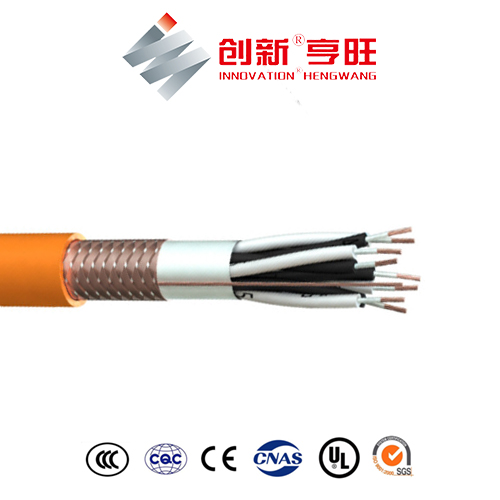

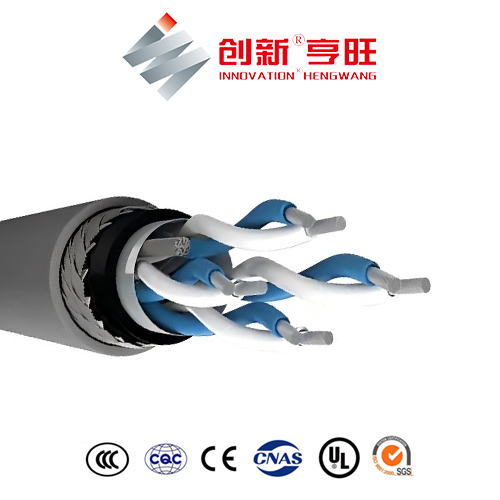

Marine & Offshore Cable

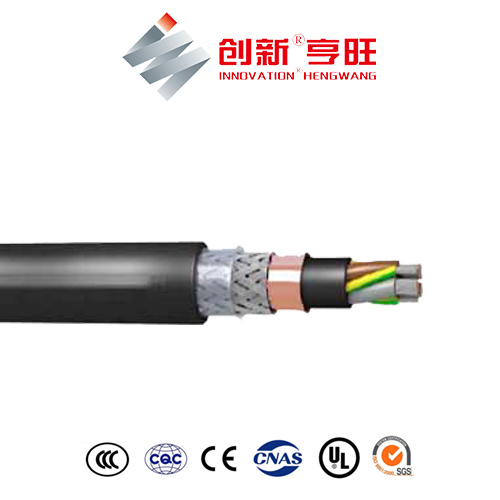

Offshore and marine cables are specialized types of cables designed for use in harsh environments such as oceans, seas, and other water bodies. They are used primarily in offshore oil and gas platforms, marine renewable energy installations (such as offshore wind farms and tidal energy facilities), telecommunications, and undersea research applications. IEC60092 Standard Offshore & Marine unarmoured power & control cables are used on board of ships in all locations for fixed installations not subject to mechanical risk complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen-free. IEC60092 STANDARD Offshore & Marine armored cables are used onboard ships in all locations for fixed installations where cable protection is required. These cables are flame retardant, low smoke & halogen-free.

For use shipboard wiring, offshore platforms, and other at-sea installations for oil drilling and production. These cover power, control, signal, instrumentation and communication ship wiring applications.

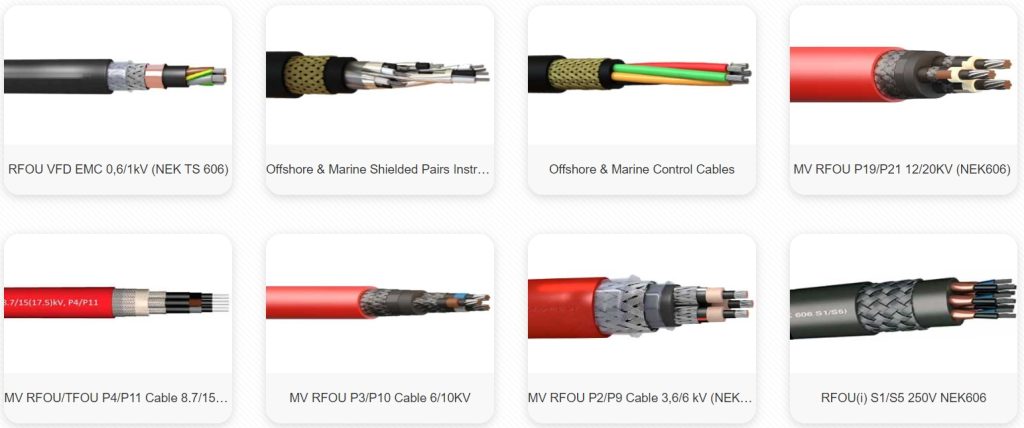

Offshore & Marine Cable Compliance and Certification:

Hengwang Cable’s offshore and marine cables adhere to specific industry standards and regulations to ensure safety and performance. Certifications such as IEC 60092 (International Electrotechnical Commission) standards, NEK 606, BS 6883, BS 7917

key features for Offshore & Marine Cable:

Durability: Offshore and marine cables are built to withstand extreme conditions including saltwater exposure, underwater pressure, and temperature variations. They are constructed with materials that resist corrosion and degradation over time.

Water Resistance: These cables are typically waterproof and designed to prevent water ingress, which can cause electrical failures or corrosion of internal components.

Strength and Flexibility: They need to be strong and flexible to withstand installation stresses, such as being pulled through water or laid on the seabed. The cables are often armored with materials like steel wires to provide mechanical protection.

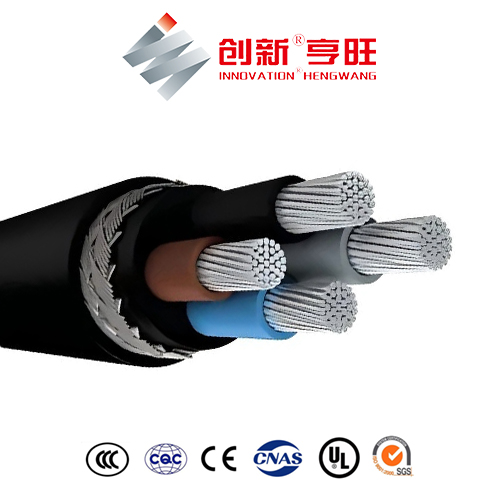

Insulation and Sheathing: Special insulation and sheathing materials are used to protect the conductors from moisture and mechanical damage. Common materials include cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) for insulation, and thermoplastic or thermoset materials for outer sheathing.

UV Resistance: Some marine cables are exposed to sunlight if they run along the seabed or are part of floating installations. UV-resistant materials are used to prevent degradation from prolonged exposure to sunlight.

Electrical Performance: Offshore and marine cables must maintain their electrical performance over long distances and undersea environments. This includes considerations for signal integrity, voltage ratings, and impedance control.

Installation Methods:

Specialized installation techniques are used for laying offshore and marine cables, such as plowing, jetting, or direct burial. Submarine cable-laying vessels are employed for large-scale installations.

Offshore & Marine Cable Application-Specific Designs:

Different applications require specific cable designs. For instance, subsea power cables for offshore wind farms have different requirements compared to those used for telecommunications or seismic monitoring. Accessing and maintaining offshore and marine cables can be challenging due to their location. Design considerations often include minimizing the need for maintenance or making it feasible using specialized equipment.

The design and selection of offshore and marine cables depend heavily on the specific application, environmental conditions, installation methods, and regulatory requirements. These cables play a crucial role in supporting offshore industries and enabling connectivity in marine environments.

IEC60092 Standard MariTox Marine Flame Retardant Power & Control Cable Specifications

| CONSTRUCTION | NOMINAL INSULATION | NOMINAL SHEATH THICKNESS MM | NOMINAL OVERALL | NOMINAL WEIGHT KG/KM |

| NO. OF CORES×CROSS | THICKNESS MM | DIAMETER MM | ||

| SECTION(MM²) | ||||

| 1×1.5 | 0.7 | 1 | 5 | 40 |

| 1×2.5 | 0.7 | 1 | 5.4 | 50 |

| 1×4 | 0.9 | 1.04 | 6.4 | 70 |

| 1×6 | 0.9 | 1.04 | 7 | 90 |

| 1×10 | 0.9 | 1.04 | 7.9 | 130 |

| 1×16 | 0.9 | 1.04 | 8.9 | 190 |

| 1×25 | 0.9 | 1.1 | 10.4 | 295 |

| 1×35 | 0.9 | 1.1 | 11.7 | 380 |

| 1×50 | 1 | 1.2 | 13.3 | 510 |

| 1×70 | 1.1 | 1.3 | 15.5 | 720 |

| 1×95 | 1.1 | 1.3 | 17.4 | 970 |

| 1×120 | 1.2 | 1.4 | 19.4 | 1220 |

| 1×150 | 1.4 | 1.5 | 21.5 | 1505 |

| 1×185 | 1.6 | 1.5 | 23.8 | 1865 |

| 1×240 | 1.7 | 1.6 | 26.7 | 2420 |

| 1×300 | 1.8 | 1.7 | 29.6 | 3015 |

Multi Cores

| CONSTRUCTION | NOMINAL INSULATION

THICKNESS MM |

NOMINAL SHEATH

THICKNESS MM |

NOMINAL OVERALL

DIAMETER MM |

NOMINAL WEIGHT KG/KM |

| NO. OF CORES×CROSS | ||||

| SECTION(MM²) | ||||

| 2×1.5 | 0.7 | 1.1 | 8.4 | 80 |

| 2×2.5 | 0.7 | 1.1 | 9.2 | 100 |

| 2×4 | 0.9 | 1.1 | 11.1 | 135 |

| 2×6 | 0.9 | 1.2 | 12.4 | 185 |

| 2×10 | 0.9 | 1.2 | 14.1 | 270 |

| 2×16 | 0.9 | 1.3 | 16.4 | 400 |

| 2×25 | 0.9 | 1.3 | 18.8 | 700 |

| 2×35 | 0.9 | 1.3 | 21.4 | 930 |

| 2×50 | 1 | 1.3 | 24.2 | 1290 |

| 3×(G)1.5 | 0.7 | 1.1 | 8.8 | 100 |

| 3×(G)2.5 | 0.7 | 1.1 | 9.8 | 130 |

| 3×(G)4 | 0.9 | 1.2 | 12 | 190 |

| 3×(G)6 | 0.9 | 1.2 | 13.2 | 250 |

| 3×10 | 0.9 | 1.3 | 15.2 | 380 |

| 3×16 | 0.9 | 1.3 | 17.5 | 560 |

| 3×25 | 0.9 | 1.5 | 20.7 | 875 |

| 3×35 | 0.9 | 1.6 | 23.5 | 1220 |

| 3×35 (sector shaped) | 0.9 | 1.5 | 20.1 | 1135 |

| 3×50 | 1 | 1.7 | 26.7 | 1780 |

| 3×50 (sector shaped) | 1 | 1.7 | 22.8 | 1530 |

| 3×70 (sector shaped) | 1.1 | 1.8 | 26.7 | 2150 |

| 3×95 (sector shaped) | 1.1 | 1.9 | 30.2 | 2900 |

| 3×120 (sector shaped) | 1.2 | 2.1 | 34 | 3675 |

| 4×(G)1.5 | 0.7 | 1.1 | 9.6 | 120 |

| 4×(G)2.5 | 0.7 | 1.1 | 10.7 | 165 |

| 4×(G)4 | 0.9 | 1.2 | 13.2 | 240 |

| 4×(G)6 | 0.9 | 1.2 | 14.5 | 320 |

| 4×(G)10 | 0.9 | 1.3 | 16.7 | 490 |

| 4×(G)16 | 0.9 | 1.4 | 19.5 | 740 |

| 4×(G)25 | 0.9 | 1.5 | 22.8 | 1145 |

| 4G35 | 0.9 | 1.7 | 26 | 1515 |

| 4G50 | 1 | 1.8 | 29.7 | 2340 |

| 5×(G)1.5 | 0.7 | 1.1 | 10.5 | 145 |

| 5×(G)2.5 | 0.7 | 1.2 | 11.9 | 205 |

| 5G6 | 0.9 | 1.3 | 16.1 | 400 |

| 5G16 | 0.9 | 1.5 | 21.6 | 920 |

| 6×1.5 | 0.7 | 1.2 | 11.6 | 180 |

| 7×1.5 | 0.7 | 1.2 | 11.7 | 195 |

| 8×(G)1.5 | 0.7 | 1.2 | 12.7 | 225 |

| 10×1.5 | 0.7 | 1.3 | 14.8 | 275 |

| 12×1.5 | 0.7 | 1.3 | 15.3 | 315 |

| 16×1.5 | 0.7 | 1.4 | 17.2 | 410 |

| 19×1.5 | 0.7 | 1.4 | 18.1 | 470 |

| 24×1.5 | 0.7 | 1.5 | 21.3 | 620 |

| 5×2.5 | 0.7 | 1.2 | 11.9 | 210 |

| 7×2.5 | 0.7 | 1.2 | 13.2 | 280 |

| 12×2.5 | 0.7 | 1.3 | 17.4 | 460 |

| 19×2.5 | 0.7 | 1.4 | 20.6 | 690 |

| 24×2.5 | 0.7 | 1.5 | 24.3 | 880 |

| 27×2.5 | 0.7 | 1.5 | 24.6 | 970 |

| 37×2.5 | 0.7 | 1.6 | 27.7 | 1300 |

Case Video

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

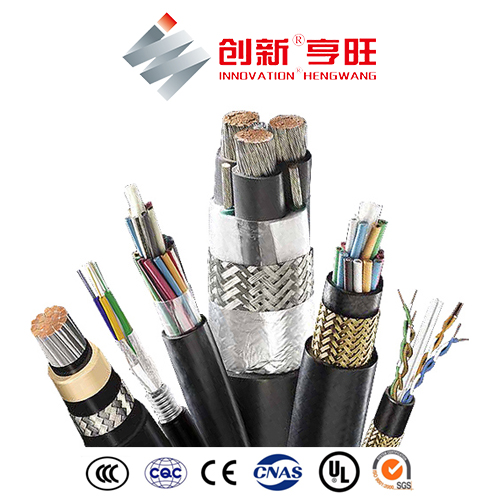

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

Originated in 2004, Hengwang Cable specializes in manufacturing a comprehensive range of electric wires and cables with rated voltages from 300V to 110kV.

our products

NEED HELP

Contact Info

- Email: inquiry@hengwangcable.com

- Phone: +86 13838542578

- WeChat: +86 13838542578

- WhatsApp: +86 13838542578

- Address: Northeast of Xinghu Road, Huji Town, Huimin County, Binzhou City, Shandong Province

© Copyright 2025 by Shandong Hengwang Cable Co., Ltd. All Rights Reserved.